Dual Channel RF Power Meter Designs

Usage

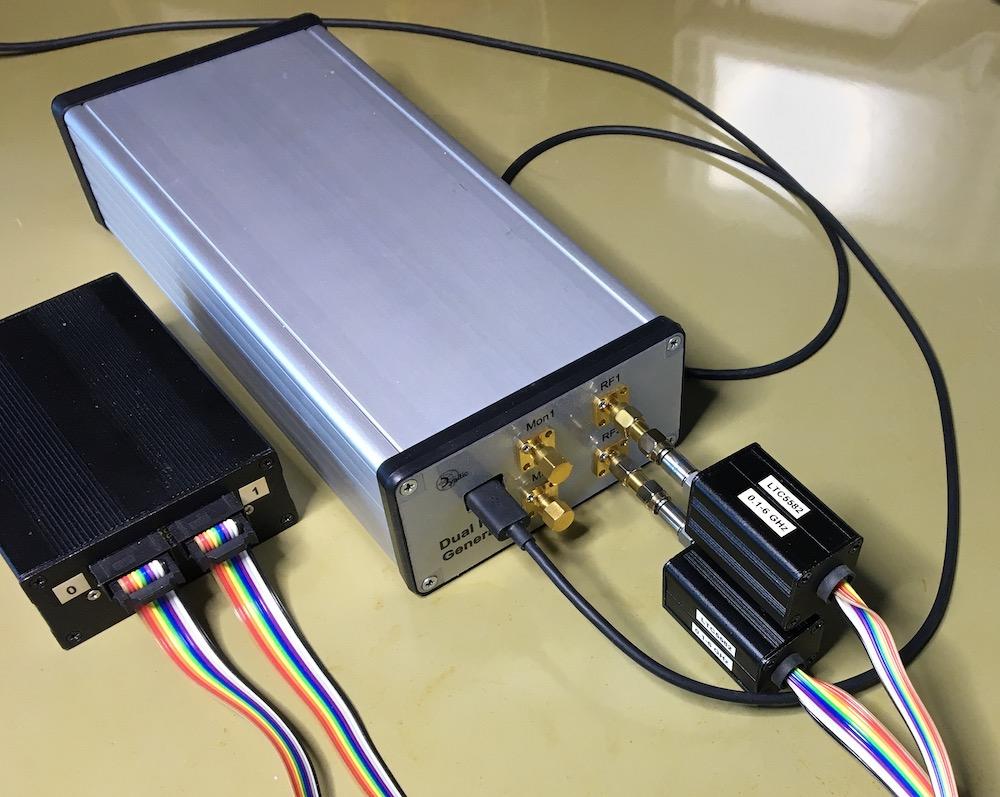

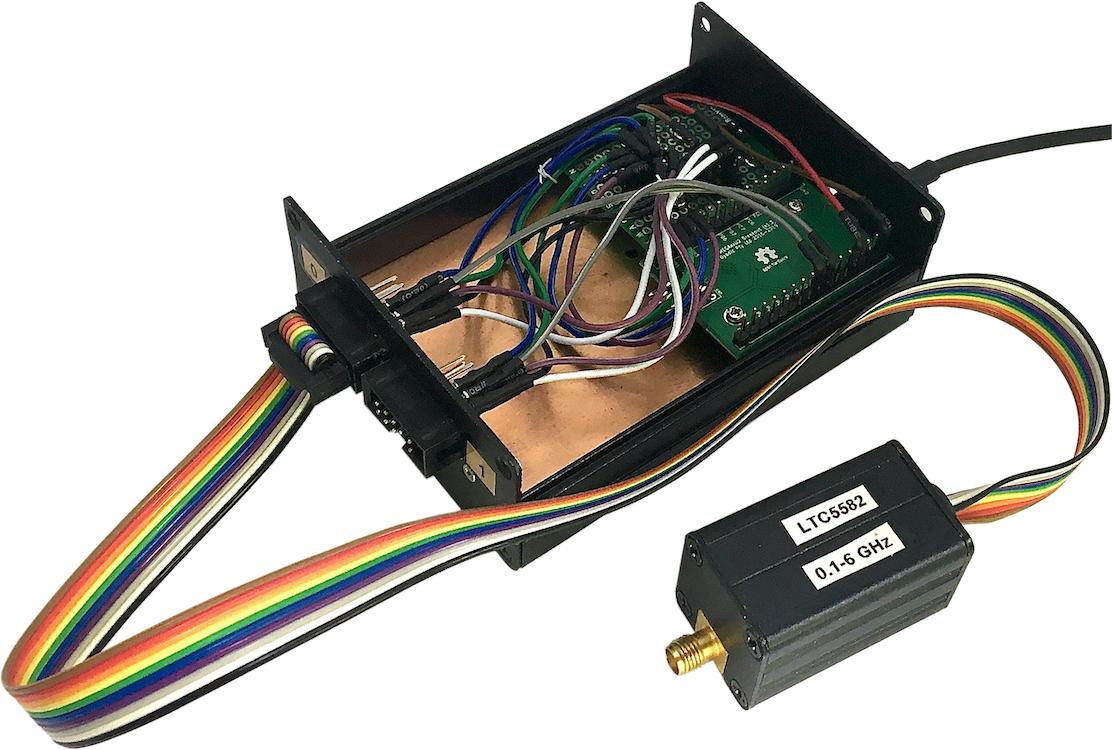

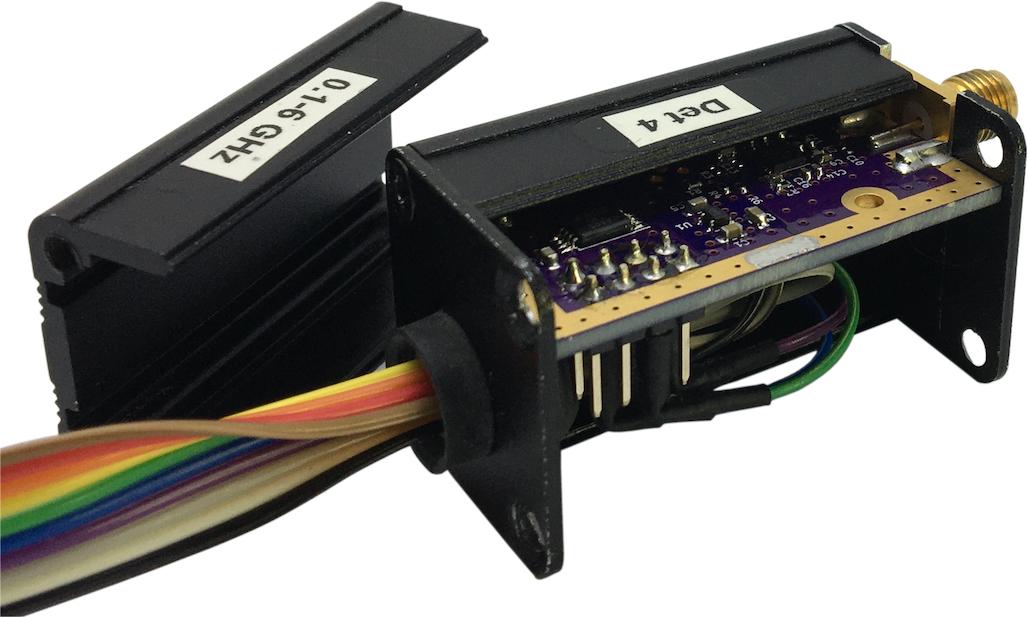

The power meter consists of two power detector 'heads'. Depending on the frequency response requirements of measurements, these heads may contain either an LTC5582 RF detector board or an LT5537 detector board. Power and SPI connections for the detector heads are taken from a small enclosure containing the controller which is connected to a host computer via USB.

Figure 1 A power meter calibrating a dual RF signal generator.

Initialization

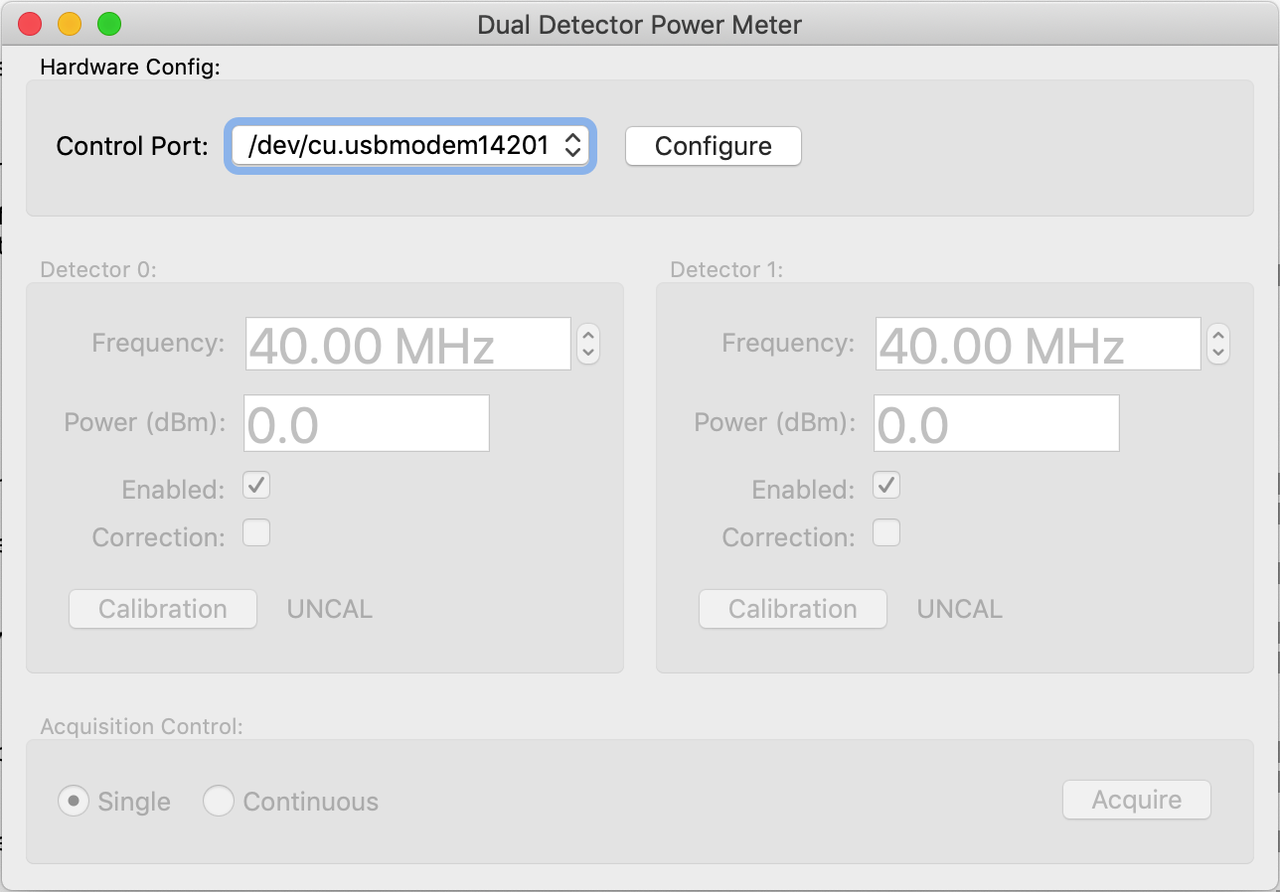

At startup the USB/RS232 serial control port associated with the

power meter app is selected from the Control Port drop down menu.

The power meter app is then configured for use with the hardware by

selecting the Initialize button.

The initialization process first initializes the power detectors connected to the power meter. This includes loading the detector hardware calibration information. After hardware initialization the app on screen UI is initialized and enabled.

Figure 2: Power meter at startup

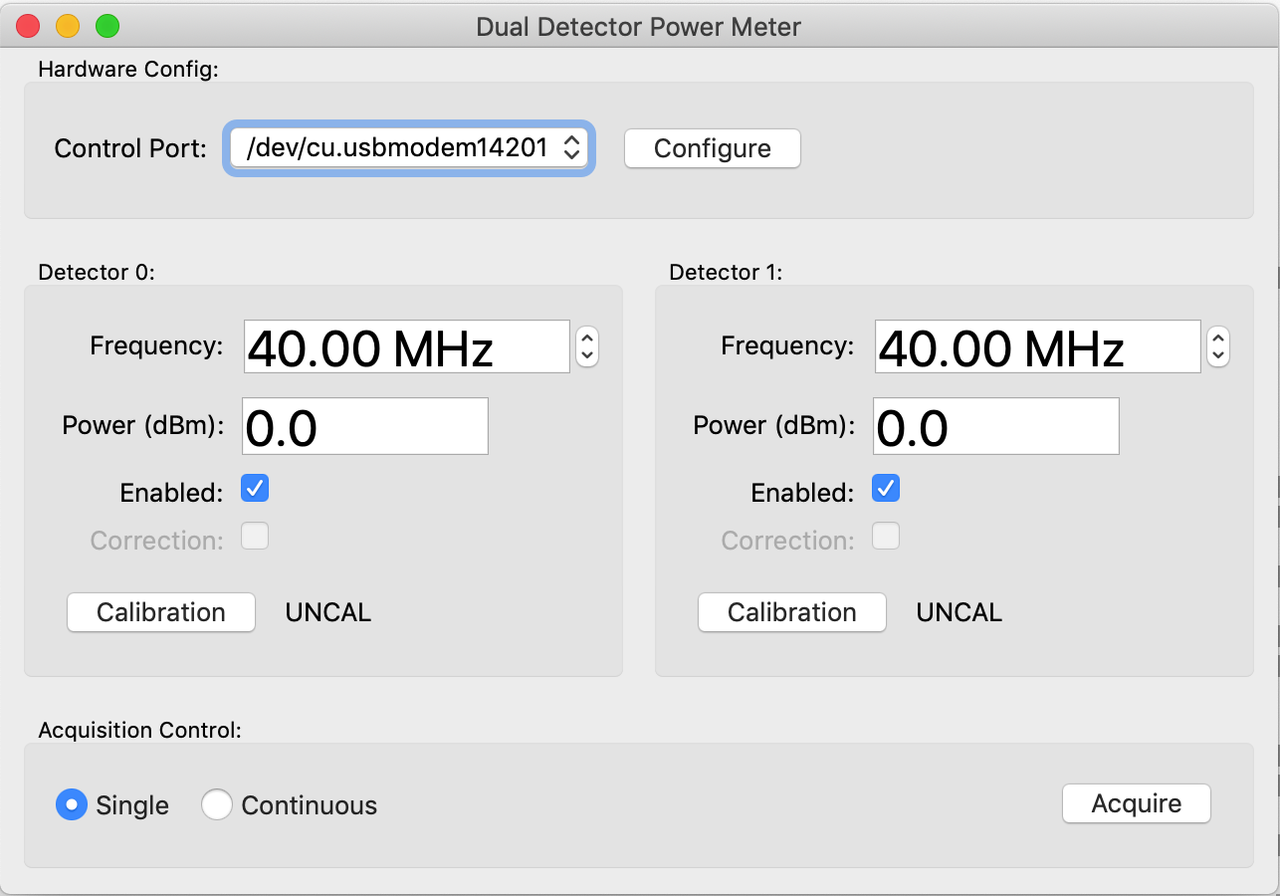

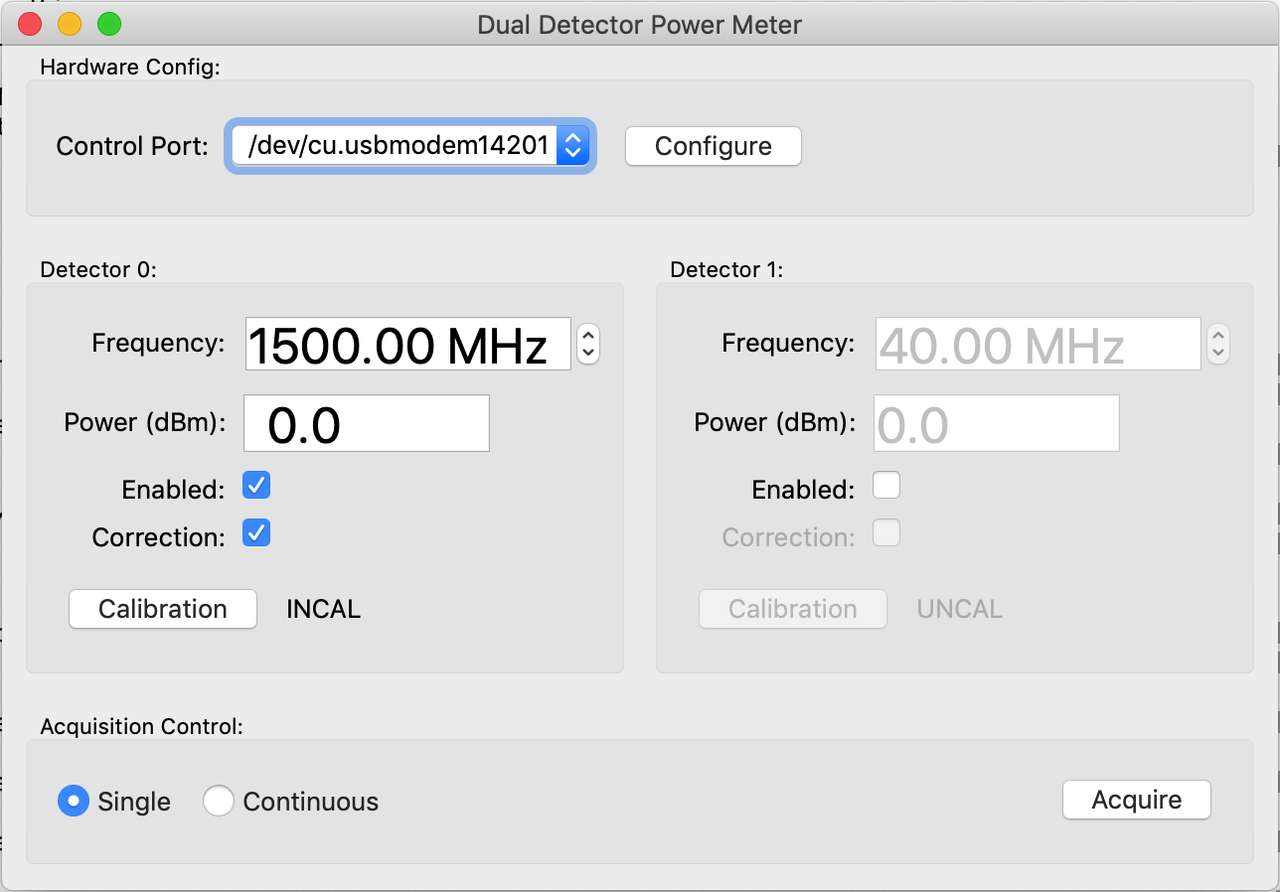

Configuration

After initialization both power meter detectors are available for use. An unused detector can be disabled if desired although this isn't absolutely necessary. Disabling a detector will disable the associated user interface controls.

Measurements are taken by first entering the signal frequency and

then selecting the Acquire button. By default this will carry out

a single signal power measurement on each enabled detector.

Figure 3: Power meter configured

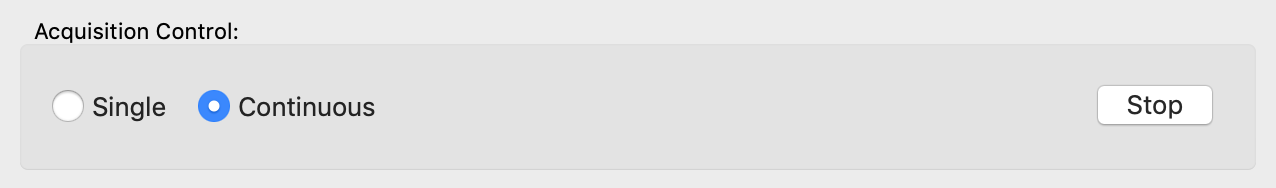

Continuous signal power measurements are enabled by selecting the

Continuous button in the Acquisition Control panel and then

selecting Acquire. Power measurements will now be continuously

taken for each enabled detector until the Stop button is selected.

Figure 4: Power meter continuous acquisition

Calibration and correction

In general, power detectors will be connected to the device under

test via some intermediate set of cabling and other devices. For

example, if the expected signal power to be measured is outside the

linear range of the detector then either attenuation or amplification

must be included. Similarly, cable losses must be corrected. What

is required is for the calibration plane of the detector to be moved

from the detector's connector to the connector which is mated with

the device under test. Initially, the power detectors are in the

UNCAL state as shown by the calibration state indicator next to the

Calibration button.

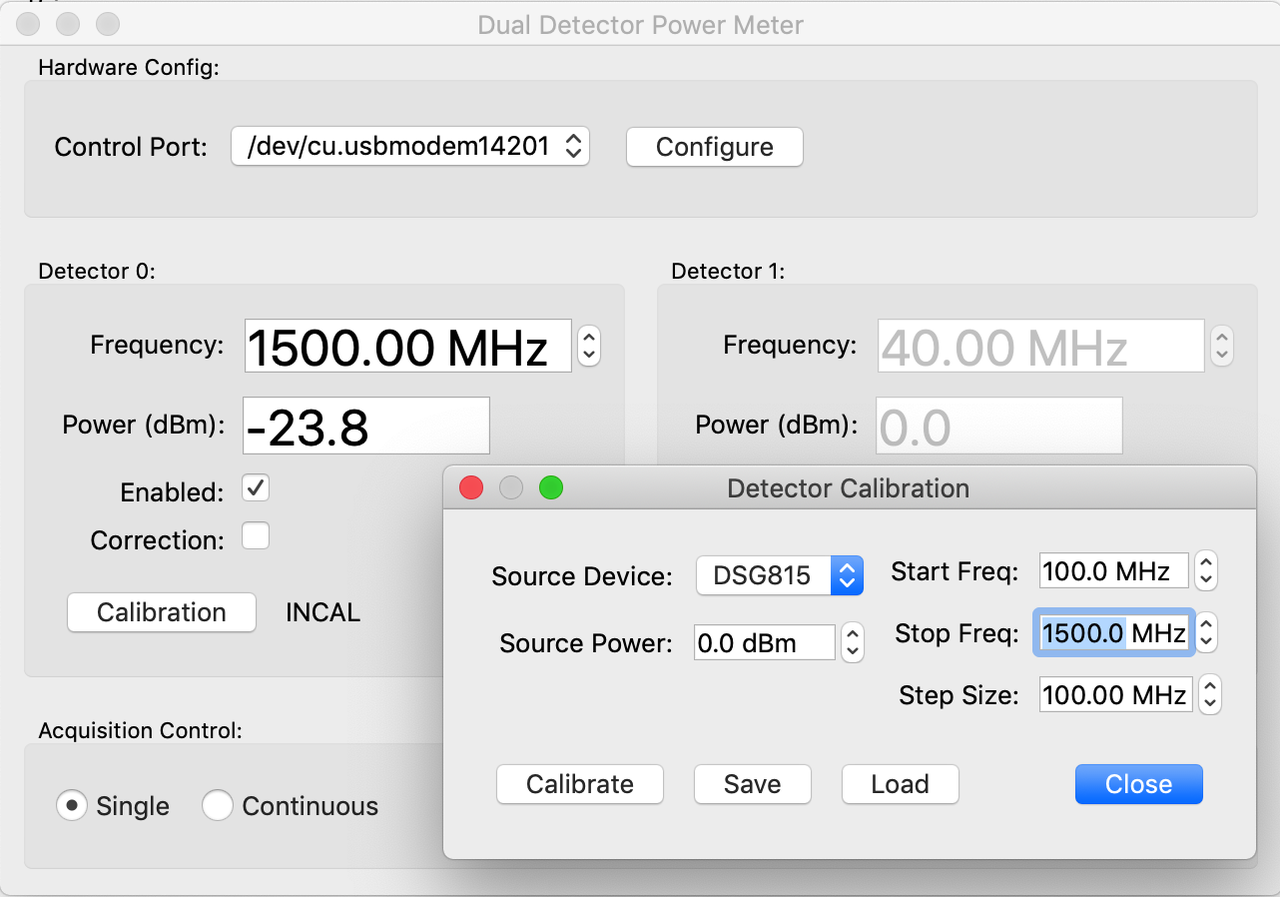

In order to generate calibration data for a given measurement setup,

the Detector Calibration facility may be accessed by selecting the

Calibration button associated with the detector in question.

Calibration data may either be loaded from a previously saved data

set or generated using a known signal source.

Figure 5: Typical power meter calibration setup

The detector, including any intermediate cables, connectors,

attenuation or amplifiers should be connected to a signal generator

which covers the frequency range of interest. A suitable signal

source power is entered together with the range of frequencies

covering the measurements which will be taken. Selecting the

Calibrate button now generates the required calibration data. This

data may optionally be saved to a file.

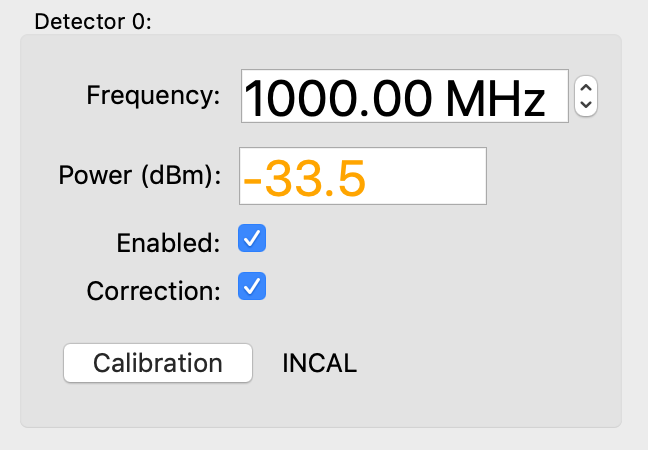

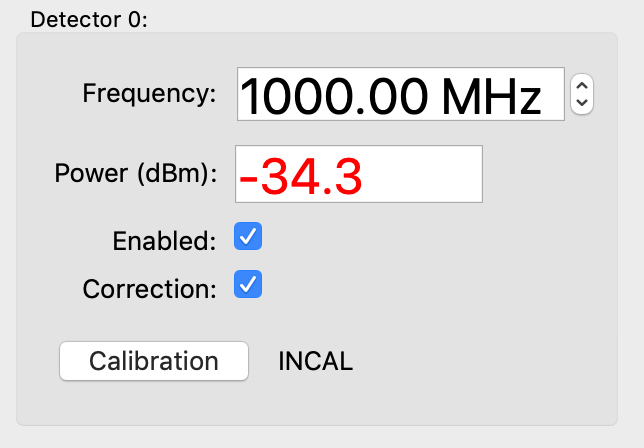

Once the app has access to valid calibration data the calibration

state indicator for the detector will change to INCAL.

Figure 6: Power meter detector calibration

To make use of calibration data to apply corrections to detector

power measurements, select the Correction check box. All power

measurements acquired by the associated detector will now have a

correction applied before being displayed. Note that if a signal

frequency outside the valid calibration range is entered the

calibration indicator will change to UNCAL and corrections will not

be applied.

Figure 7: Power meter using calibrated correction

Generating calibration data from S-parameter measurements

Measurements

Power detector measurement within 0.5dB of non-linear region

Power detector measurement is in non-linear region

Extending the power measurement range

Software control

Software control of the power meter is done via the PwrMeterService

RPyC service provided by the power meter reference design app. The

service API is given here: The pwrmeter Service.

Before running the rpyc client example code below the power

detector app should be started:

Note that the command serial device must either be specified on the

command line as above or selected from the Control Port drop down list

once the app is running and displayed on-screen. If the app is run

'headless' (by specifying the '--nogui' command line option) then the

serial device must also be specified via the command line.

By default the pwrmeter service will listen on port 18863 of

the localhost interface. This may be changed by using the -P and -A

command line options when starting the app.

import rpyc from tam import DSG815_ID pwrmeter = rpyc.connect('127.0.0.1', 18863) pwrmeter.root.initialize() chan_controllers = pwrmeter.root.detectors chan_ctl0 = chan_controllers[0] chan_ctl1 = chan_controllers[1] # Calibration is a long running process and the calibrate call # is synchronous. The rpyc request timeout should be either # disabled or set to a long period so that a timeout isn't triggered old_timeout = pwrmeter._config['sync_request_timeout'] pwrmeter._config['sync_request_timeout'] = None status = pwrmeter.root.calibrate(0, 'DSG815', DSG815_ID, 0, 0.0, 100.0, 1500.0, 100.0) pwrmeter.root.calstatus[0] # should return 0 # Restore the rpyc request timeout value pwrmeter._config['sync_request_timeout'] = old_timeout chan_ctl0.freq = 500.0 pwrmeter.root.measure(0) pwr = chan_ctl0.pwr chan_ctl0.apply_correction = True pwrmeter.root.measure(0) corrected_pwr = chan_ctl0.pwr chan_ctl1.freq = 150.0 pwrmeter.root.measure(1) pwr = chan_ctl1.pwr pwrmeter.close()

Design Notes

Figure 8: Power meter schematic design.

Assembly

Figure 9a: Power meter assembly

Figure 9b: Power head assembly

The Power Meter App Source Code

A full description and code for the power meter app is given here: pwrmeter.py.